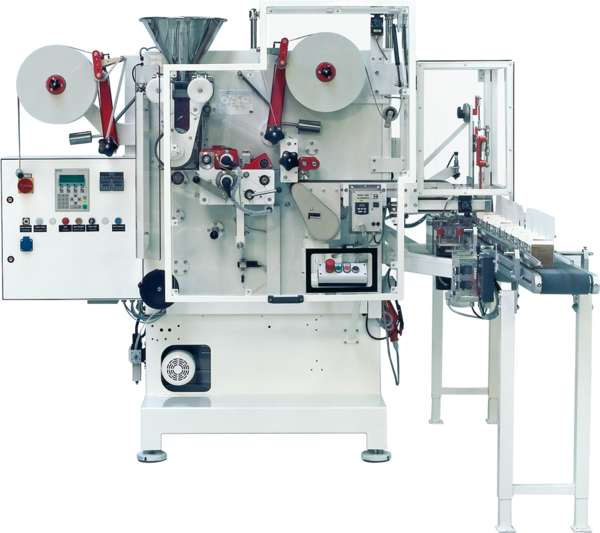

HST PT-6 Series

Basic Description

The PT-6 type machinery produces rectangular single chamber teabags (without string and tag) by edgesealing seams at 4 sides using heatsealable filter materials.

There are two versions:

- PT-6.2 : Produces teabags in 2 lanes.

- PT-6.4 : Produces teabags in 4 lanes.

The high speed PT-6.4 is our flagship model which can produce up to 1.000 teabags per minute. The smaller version is the PT-6.2 which produces up to 500 teabags per minute. In each case, a pair of 2 bags are kept together by thin nose-pieces so they keep together and can be handled more accurately, but teared very easily by the consumer.

Because the machines use 2 separated reels of filter material, they are able to produce teabags with 2 different materials on each side, for example filter paper on the downside and a more transparent non-woven fibrous fleece or a fully transparent PE mesh on the upside, which leads to an unique optical effect: Through the mesh, one can see, smell and feel the tea against the intransparent white filter paper background and enjoy it with all senses.

The machine is extraordinally reliable and effective.

Bag Size Options: S | L

The following teabag sizes are possible:

- S : Standard bag size 65 x 61 mm.

- L : Larger bag size 65 x 71,5 mm.

The machines are not convertible between bag sizes.

Packing Options

For the finishing packing there is a manual and a automated option:

- In the hand pack version the teabags are stacked on a conveyer belt for filling pre-erected boxes or for manual end packing.

- The full automated versions (with cartoning) stack the teabags fully automatically into a carton box. Due to the top-loaders thoroughly concerted movements, the bags are layed down very neatly into the box.

In our optional high end version, a KA-20 carton erector preproduces the carton boxes from flat blanks with a hotmelt gluing system and feeds these open boxes to the machine. After filling, the boxes are check-weighed and forwarded to a lid-closener. Finally the box can be glued to get shelf-ready without a cellophane wrapping. Additionally an ink-jet system can mark the boxes with best before date and lot number.

Key Advantages

- 100% German engineering

- Reliable mechanical technology

- Long life cycle

- Compact size

- Filter material combinations possible

- Easy assembly, operation and maintenance

- Low maintenance and spare part costs

- Very low energy consumption

- Reasonable machine price

- High flexibility also for small production lots

We are constantly developing our machines. All pictures show realized machines, which may have been subject to technical improvements. Appearance and details may therefore change.